Air Dispersion Dryers

Product Details:

- Inlet Temperature Ambient to 120C

- Power Consumption 6-18 kW

- Air Flow Adjustable

- Power Output Variable, based on model

- Heating Power 9-15 kW

- Dimension (L*W*H) 1800 x 1200 x 1600 mm

- Drive Direct Drive

- Click to View more

X

Air Dispersion Dryers Price And Quantity

- 1 Unit

Air Dispersion Dryers Product Specifications

- India

- Automatic Oil Lubrication

- AC Power

- Up to 180C

- Ambient to 120C

- Variable, based on model

- 9-15 kW

- <0.1 ppm

- 1800 x 1200 x 1600 mm

- Three Phase

- 6-18 kW

- Electric

- Adjustable

- <75 dB

- 0.5-0.8 MPa

- 1200-3000 m/h

- 700 mm

- 50-150 L

- Direct Drive

- 380 V

Air Dispersion Dryers Trade Information

- 1 Unit Per Month

- 3-4 Week

Product Description

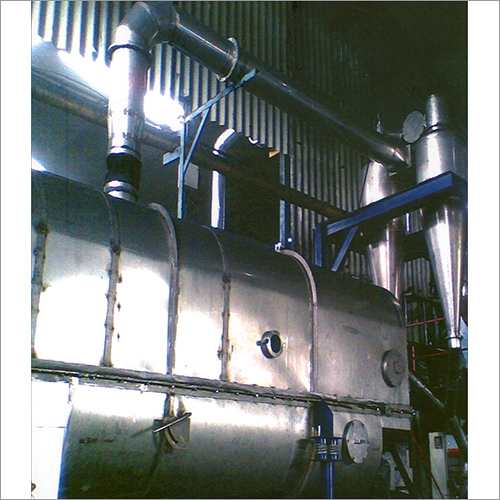

We are proposing a broad collection of strategically manufactured Air Dispersion Dryers. They aid in removal of water vapors from compressed air. These dryers are widely utilized in commercial and industrial sectors. They can be taken in various types by clients to perfectly match their exact requirements. Air Dispersion Drying Plants have a hard bitten structure, efficient performing capability, impact resistance and rust proof body. They offer an easy operation and does not add to any kind of pollution.

Features Of Air Dispersion Drying Plant:

- Low maintenance

- High efficient

- Low power consuming

- Reliable performance

Air Dispersion Dryer Technical Details:

- Dryer Horse Power : 5 HP

- Maximum Pressure : 10 bar

- Frequency : 50 Hz

- Material : Stainless steel

- Surface Treatment : Color Coated

- Max Temperature : 220 Deg C

- Min Capacity : 250 Cfm

- Max Capacity : 2000 Cfm

Advanced Drying Technology

Featuring state-of-the-art drying capabilities, the Air Dispersion Dryers deliver exceptional moisture removal. The combination of automatic humidity control, up to 180C temperature range, and adjustable air flow ensures fast and consistent results for various types of raw materials and end products. These dryers support bottom discharge for streamlined product handling.

Smart and Safe Operation

Engineered for operator safety and ease of use, the dryers come equipped with a digital touch control panel and LED indicators. Overheat and overcurrent protections guarantee safe working conditions, while the automatic oil lubrication system reduces maintenance requirements and supports continuous heavy-duty use in industrial facilities.

Optimal Build and Installation

Built from polished Stainless Steel 304 and sized for floor mounting, each unit requires professional installation to maximize efficiency and longevity. The direct drive, quiet operation (<75 dB), and precise control features make these dryers an excellent fit for pharmaceutical, food, and chemical plants seeking high-quality, durable solutions.

FAQs of Air Dispersion Dryers:

Q: How should the Air Dispersion Dryer be installed for optimal performance?

A: Professional installation is recommended to ensure safe and efficient operation. The floor-mounted design and three-phase electrical requirements mean that a qualified technician should handle setup, connection, and initial calibration.Q: What are the key benefits of using a stainless steel 304 construction in these dryers?

A: Stainless Steel 304 provides superior corrosion resistance, durability, and hygienic surfaces ideal for food processing, pharmaceuticals, and chemical industries. It also ensures compliance with rigorous safety and cleanliness standards.Q: When is automatic humidity control required during operation?

A: Automatic humidity control functions throughout the drying process to maintain target moisture levels, enhancing drying accuracy and consistency, which is especially critical for sensitive pharmaceutical and food products.Q: Where can these dryers be used most effectively?

A: These dryers are designed for versatile use in pharmaceutical plants, food processing facilities, and chemical manufacturing units where high drying efficiency, hygiene, and reliability are paramount.Q: What process does the dryer follow to manage overheat and overcurrent situations?

A: Integrated safety systems monitor temperature and electrical current continuously. If an unsafe condition is detected, the dryer automatically shuts down or adjusts its operation to prevent damage and protect both equipment and operators.Q: How does the automatic oil lubrication feature improve usage?

A: Automatic oil lubrication ensures all moving components are adequately lubricated, minimizing wear and reducing maintenance needs, thus supporting uninterrupted operation in industrial settings.Q: What are the main advantages of the digital touch control and LED indication display?

A: These features provide intuitive operation, allowing users to monitor key parameters such as temperature, humidity, and system status at a glance while making adjustments easily for precise control over drying conditions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email